Vapor Blasting with ARMEX

ARMEX is the Only Choice

When cleaning surfaces or substrates that cannot be damaged, the only blasting abrasive to use is ARMEX. The gentle physical propriety of baking soda but yet aggressive cleaning ability is what makes ARMEX the only choice. Other hard blasting abrasives can remove surface material from substrates causing permanent damage especially when the operator performing the blasting is not an experienced blaster. ARMEX gentle physical propriety is forgiving to compensate for inexperienced blasters as well as over blasting. Additionally ARMEX is also soluble. A freshwater rinse after blasting will prevent surface contamination by never leaving blast particles behind.

Use on a wide variety of substrates including:

- Steel

- Lead

- Aluminum

- Alloys

- Plastics

- Composites/fiberglass

- Wood

- Masonry materials

Use ARMEX to clean, and remove:

- One and two part coatings

- Grime

- Burnt on carbon

- Fire Damage/soot

- Mold

- Grease and oil

- Rust

- Oxidation

ARMEX the Original Baking Soda Abrasive

Sodium Bicarbonate (baking soda) abrasive blasting originated back in the 1980’s during the restoration of the Statue of Liberty. During the planning of the project, Church & Dwight Co., Inc. maker of ARM & HAMMER™ baking soda was contacted by the engineers looking for a way to remove the final two interior coating layers without damaging Lady Liberty’s delicate copper skin.

Through trial and error the engineers tested many different blasting abrasives and discovered that Sodium Bicarbonate had extraordinary cleaning and coating removal properties while not causing any surface damage. Following this success, Church & Dwight Co., Inc. launched the first Sodium Bicarbonate blasting abrasive, ARMEX.

Not All Sodium Bicarbonates are the Same

ARMEX formulations are unique and distinct from other Sodium Bicarbonate blasting abrasives. Sodium Bicarbonate comes in different grades of material which affects product quality and consistency. ARMEX formulations are manufactured in a consistent process and controlled environment using the highest grade of Sodium Bicarbonate available. This is what makes ARMEX the most consistent and highest quality Sodium Bicarbonate on the market.

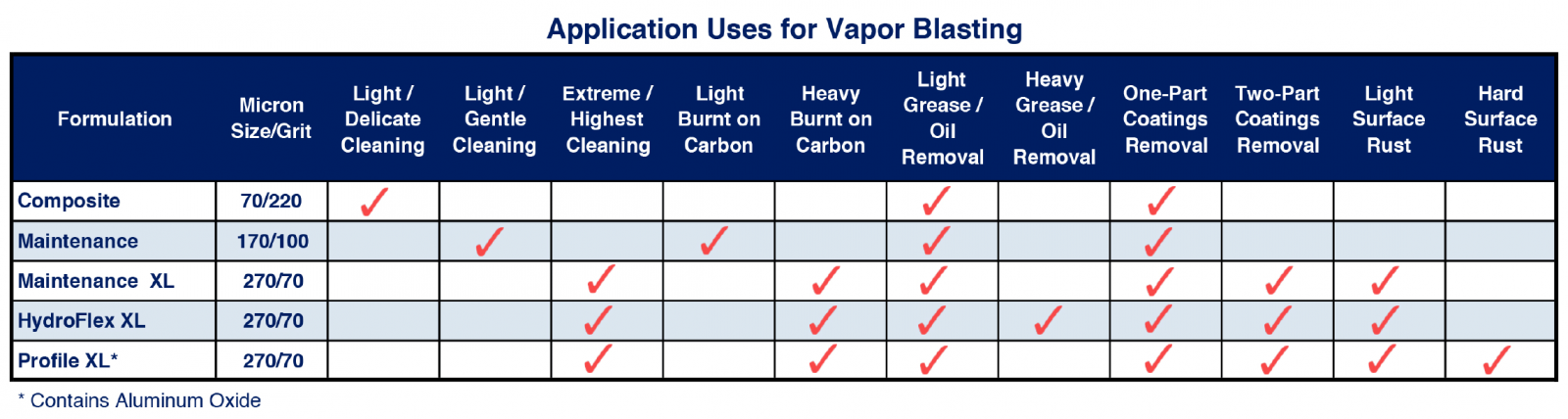

ARMEX Sodium Bicarbonate comes in different granule sizes ranging from 70 to 270 microns. The micron size will determine the degree of aggressiveness of cleaning with 270 microns providing the highest/extreme level of cleaning and 70 microns for more light/delicate cleaning.

An additional benefit of ARMEX products are flow aids and advance moisture control additives which will prevent vapor blast equipment from clogging. Sodium Bicarbonate is a natural desiccant and loves to absorb water. Without these flow aids and advance moisture control additives, traditional Sodium Bicarbonates would clog vapor blast equipment,. In addition it helps to preserve ARMEX when stored in high moisture environments.

Vapor Blasting with ARMEX

Vapor blasting uses a smaller quantity of water than conventional water blasting. ARMEX can be used in vapor blasting equipment with no modifications to the equipment. This allows vapor blasters to take advantage of ARMEX abrasive cleaning benefit of substrate preservation.

ARMEX is introduced into the vapor blast pressure vessel in the same manner as other abrasive medias. The change in process from a hard abrasives media to ARMEX is the need to use a slightly larger differential pressure to achieve the desired media flow rate from the equipment. This is not a surprise as ARMEX is lighter in density than most other harder abrasives used in vapor blasters. Vapor blasters also eliminates most of the dust previously created when dry blasting with baking soda and consumes less media making vapor blasting the most effective and efficient way to use ARMEX.