Frequently Asked Questions

Get answers to your frequently asked questions about ARMEX, soda blasting, benefits, uses and more. Just click on the questions below.

Abrasive blasting is the projection at a surface of a suspended particulate in a pressurized air or water stream for the purpose of removing a coating or contaminant, or other alteration of that surface in some way.

One of the most important differences between abrasive blasting with sodium bicarbonate (baking soda) versus abrasive blasting with any other abrasive medias are that baking soda’s attributes allow it to remove contaminants without damaging the underlying substrate.

Sodium bicarbonate is the ideal abrasive blasting media for the removal of oil and grease.

ARMEX is a baking soda based (sodium bicarbonate, NaHCO3) media manufactured by the makers of ARM & HAMMER™ Products for use as an abrasive in cleaning or removing coatings without alteration of the base material. There are 11 formulations sold by a network of distributor worldwide.

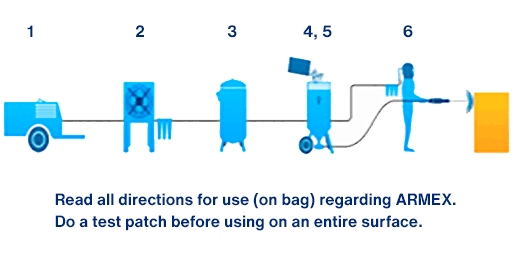

- Air supply adequate CFM for nozzle size and desired blast pressure

- After cooler*

- Moisture separator*

- ARMEX® Blast Media

- Blast pot, hose and nozzle

- Personal protection equipment

*Optional depending on air quality

ARMEX Standard, Premium and Specialty formulas are effective for cleaning precision components, engine rebuild applications, delicate substrates and composite materials, architecture and masonry, processing and manufacturing equipment.

The Profile Formulas are effective when rust, heavy paint or tenacious contamination removal, or profiling is required and substrate preservation is not a concern.

No. While all baking soda is chemically the same (NAHCO3) only ARMEX is formulated for use as a blast media and only ARMEX is manufactured by ARM & HAMMER™. Formulations contain uniform particle sizes from 70-270 microns, and ingredients for flowability and rinsabilty. The profile formulas are uniquely blended for more aggressive removal applications.

No. You cannot recycle ARMEX. It is considered a one-pass media. Unlike other abrasives ARMEX is extremely friable meaning that it fractures into much smaller particles upon impact. This not only results in a more intense cleaning action and softens the impact on substrates, but also transforms the particle to a fine dust no longer suitable for coatings removal.

Using ARMEX with the right equipment maximizes cleaning efficiencies and minimizes media use, often providing greater productivity because concern for surface damage even at high pressures is minimal. For this reason users have found the ARMEX process to be either more, or as cost effective as other abrasive processes.

In contrast, higher priced recyclable abrasives like plastic or glass bead, will degenerate at blast pressures over 45 psi reducing their recyclability, though their cost remains much higher. Increasing blast pressure with these media therefore not only increase cost but also increases the risk for surface damage

In air driven applications ARMEX can be used dry or wet. When used wet with water as a dust suppressant dust will generally fall within 10ft of the work piece. When used dry, in a portable application, containment for migrating dust may be required or other mitigating measures such as negative air chambers or air scrubbers can be used. In process production or remanufacturing applications glove box units, or fully contained cabinet systems, blast rooms or partial enclosures are available. See “What if I already have a blaster or cabinet?”

Yes. There are media injection devices available to introduce ARMEX into the water stream of your pressure washer, operating at 3,000 psi or above. These attachments are available through the authorized ARMEX distributor network. Most pressure washer applications are appropriate for cleaning only or light coatings removal like “tagging.”

Yes. All blasting operations require safety precautions for the worker and environment. You must take into account not only the abrasive being used but also the coating being removed and the environment in which you are operating. The coating content may dictate additional containment, waste disposal and worker safety requirements. ARMEX however simplifies all concerns because it has a 0 HMIS rating and therefore adds no hazards to a project. Personal Protection Equipment is essential for operators, during any blasting operations and care should be taken for protection of the surrounding area with regards to people, and the environment.

Using ARMEX around plant life and grass can be an issue. One biological process that can be disturbed by the presence of any free sodium ion, including sodium bicarbonate is the process of photosynthesis. This process uses light in the presence of chlorophyll and water to convert carbon dioxide to sugars, the plant life nutrient. Depending on the type of plant, sodium bicarbonate can produce temporary discoloration or cause more serious damage.

The most easily upset plants are flowering shrubs, such as roses, azaleas, or lilac. Trees and grass typically turn brown, then recover in 4-6 months. Some plants are completely unaffected. The speed of any reaction with plant life can vary widely, depending on the type of plant.

To avoid damage to plants from blasting with ARMEX Blast Media:

- Avoid contact between plants and blast media residue. Cover plants and prevent the liquid run-off from soaking the soil around plants.

- If contact is unavoidable, the client should be aware that damage to plants can occur.

To minimize damage:

- Soak the soil and leaves thoroughly before blasting. It is best to use a sprinkler for 4-6 hours to completely soak the soil, leaves, and branches before blasting.

- Continually rinse the leaves and prevent liquid run-off from soaking into the soil around the roots.

- After blasting, continue to soak the leaves and soil to thoroughly flush the sodium bicarbonate away from the root structure. The amount of soaking after blasting depends on the amount of residue in contact with leaves and roots. The goal is to reduce the sodium ion concentration below 0.5 vol% on the leaf surfaces and around the roots so that any damage will be minimized.

Blast Pots – It is highly recommended that equipment manufactured specifically for baking soda blasting be used in order to achieve optimum results. Even though conventional sand blast systems may be used, performance and economy will be compromised. Pressure systems will generally work better than suction systems. It is imperative that the volume of air available is appropriate for the size of the nozzle you are using and the blast pressure at which you want to operate. The larger the nozzle the more volume of air is required. Volume should not be confused with Pressure or psi available. Nozzle configuration can also impact performance. See “What kind of nozzle do I need?”

Cabinet Systems – are usually designed to recycle abrasives. ARMEX, however cannot be recycled as it is extremely friable and breaks down upon impact at any pressure. There are two consequences of this action that are addressed in a soda cabinet that are not addressed in conventional recycle cabinets. First of all, due to the dust created while blasting the visibility in the glove box may be greatly reduced. Cabinets designed for soda have addressed this issue drawing air across the view glass in order to improve visibility. Secondly, cyclone recycling systems are designed to capture and clean reusable media and feed it back into the blast stream. ARMEX being completely pulverized at any pressure, upon impact, will bypass this type of cyclone and all the dust and debris will continue on to fill the dust collector prematurely. In a cabinet system designed for soda, the cyclone drops out most of the debris, waste and spent media, up to 99%, into a drum or other receptacle and only the very fine particulate goes to the dust collector. In this way the dust collector is preserved for longer use. The drummed waste if tested as a non-hazardous industrial waste can then be easily hauled away to a sanitary landfill. These are two good reasons to invest in a dedicated soda cabinet system rather than try to use or retrofit a recycling cabinet.

Production rates are dependent on a number of variables, the coating or contamination to be removed, its thickness, the nature of the surface material being treated, the complexity of that surface, the abrasive chosen, the nozzle size and configuration, the air supply available to support the operating blast pressure and the skill of the operator. Because of all of these contributing factors, strip rates vary greatly depending upon the application variables. It is strongly recommended that a representative test area be striped in order to project media use and cost. Keep in mind that most soda systems are designed to run much leaner than conventional sand blast pots.

ARMEX is sold only through a network of authorized distributors worldwide. Prices will vary according to formula selected and volume purchased. For a sales representative in your area, click here.

The same variables exist for applications being done in cabinet systems. Keep in mind however, that due to the friability and inherent softness of the ARMEX particle, increasing blast pressures for aggressive removal of coatings or contaminants can greatly improve production rates without increasing the risk of damage. This cannot be said of other grits.

Nozzle selection is very important in determining production results. Nozzle size and type determine the volume of air needed and the size of the air compressor required to achieve the desired blast pressure. An inadequate air supply can greatly reduce performance, production rates and cost efficiencies. Some suggested nozzles to use with ARMEX are as follows:

[IMG]

ARMEX is widely used among industrial and specialty cleaning contractors. ARMEX distributors are closely associated with these contractors and can often recommend one in your area for your application. For a sales representative in your area, click here.

When it comes to abrasive blasting many people use the common term “sandblasting,” but there are several mediums that can be used. Outlined below, we outline the main difference between soda blasting, sandblasting and glass blasting.

Let’s first break the different materials into two groups: Soft Abrasives and Hard Abrasives.

Soft Abrasives

Baking soda is considered a soft abrasive. It is typically harder than the surface contaminant, but softer than the substrate. One of the most important differences between blasting with sodium bicarbonate (baking soda) – versus blasting with any other abrasive media – is that baking soda’s attributes allow it to remove contaminants without damaging the underlying substrate.

Soft abrasive blasting is excellent for cleaning materials which need to be reused. For example, remanufacturing where you don’t want to change tolerances of a part. Also, cleaning machinery on a regular basis, including food production equipment, without causing extra wear.

Hard Abrasives

“Sand” – technically aluminum oxide or silicon carbide – and glass are considered hard abrasives and additional care must be used when sandblasting or glass blasting to avoid any damage to the underlying substrate.

Hard abrasive blasting is great when you’re not worried about removing substrate material. For example, if you’re refinishing a car and need to remove heavily rusted metal.

You can learn more about various sandblasting and media blasting in our resources section.