Remanufacturing Starts with ARMEX

In remanufacturing and rebuilding of engines, transmissions, brake assemblies, turbos and/or any other components that can be rebuilt or remanufactured are highly dependent on cleaning products with thorough and dependable results.

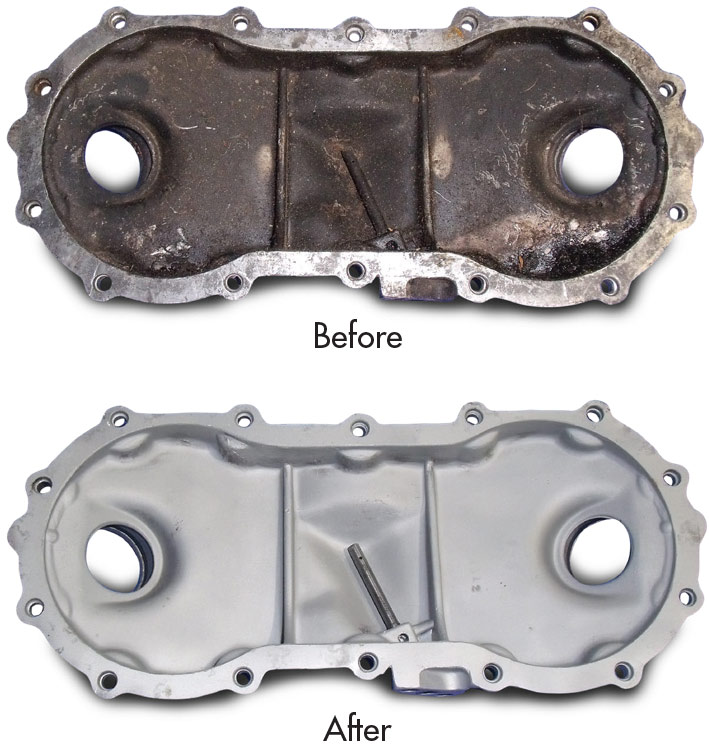

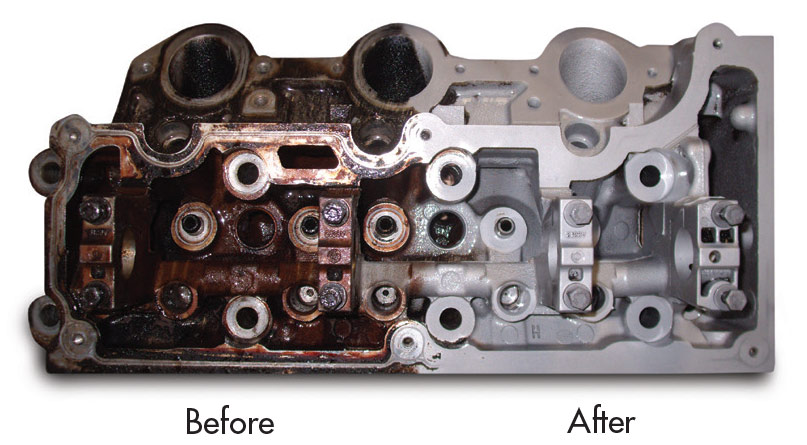

Before anything else can be done to the cores or components being rebuilt or remanufactured, it needs to be cleaned and inspected for defects. ARMEX has answered the problem of ineffective and time-consuming cleaning processes with the introduction of Re-Man XL, the first abrasive blasting media specifically formulated for the remanufacturing and rebuilding industry. Typical automotive contaminants are no match for Re-Man XL. With its extraordinary ability to quickly eliminate grease and oil plus the power to remove burnt-on carbon, light rust, gasket materials, coatings and grime all in one-step. Furthermore, Re- Man XL will never damage what you are cleaning reducing rejected cores and components. If you what to improve your cleaning process all while saving time and resources Re-Man XL is the only choice.

The Re-Man XL Advantage Features

Features:

- Non-destructive cleaning

- Environmentally friendly

- Water Soluble

- pH of 8.2

- Non-hazardous

- Non-Flammable

- Sharp and Granular

- Friable

Benefits:

- Will not damage cores components

- Safe technology, no danger to operators or environment

- Blast particles dissolve leaving no particles behind

- Nonacidic

- Poses no special handling or disposal problems

- Non-thermal sparking

- Crystalline particulate

- Fractures easily, intensifying the cleaning action

Why Use Re-Man XL

Some parts-cleaning processes involve multiple steps, such as the application of a solvent, followed by a cleaning agent, followed by rinsing. There also may be the need for pre-treatment in a chemical solvent bath or multiple treatments before a part can be considered truly clean. Re-Man XL offers a fast, thorough cleaning from a single application and freshwater rinse. But there is much more to Re-Man XL than mere efficiency. With a Mohs hardness value of 2.5, Re-Man XL is considered a soft crystal; in most cases, it’s harder than the contaminants, but softer than the underlying substrate. This is a crucial difference in terms of preserving cores and components integrity.

Only Re-Man XL can clean without causing surface damage or profiling. Hard abrasives blasting medias, by contrast can damage the surface in numerous ways, including denting, pitting, profiling and fracturing. These types of changes affect the tolerances and specifications of machined parts, rendering them unusable which is a serious consequence of blasting with hard abrasive medias.

Soda blasting continues to offer critical differences even after the blasting process is complete. Because it can clean metal surfaces without filling cracks, it’s easier to find faults during post-blasting inspection. If media such as glass or plastic beads gets stuck in the blind passageways of complex automotive components, the possibility of engine failure is significantly increased. Spent baking soda media, by contrast, can be easily rinsed away thanks to its water solubility; the liquids that normally circulate through engines and transmissions — engine oil, antifreeze, transmission fluid — will also effectively dispose of left-behind soda, never causing damage to moving parts.

Re-Man XL for an environmentally friendly, fast and safe cleaning of cores and components

Will Not:

- Change parts specifications

- Change parts tolerance

- Remove substrate materials

- Strip aluminum treads

- Damage bearing

- Leave blasting particles behind (soluble)

Safe For Use On:

- Stainless steel

- Aluminum

- Alloys

- Chrome

- Glass

- Composite & Fiberglass

- Plastics & Rubbers

Will Remove:

- Grime

- Grease & Oils

- Paint

- Burnt on Carbon

- Gasket materials

- Glues / Epoxy

- Labels/stickers

ARMEX the Original Baking Soda Abrasive

Baking soda (Sodium Bicarbonate) abrasive blasting originated back in 1986 during the restoration of the Statue of Liberty. During the planning of the project, Church & Dwight Co., Inc. maker of ARM & HAMMER™ baking soda was contacted by the engineers looking for a way to remove the final two interior coating layers without damaging Lady Liberty’s delicate copper skin. Through trial and error, the engineers tested many different blasting abrasives and discovered that Sodium Bicarbonate had extraordinary cleaning properties while not causing any surface damage. Following this success, Church & Dwight Co., Inc. launched the first Sodium Bicarbonate blasting abrasive, ARMEX in 1989.