How Soda Blasting Works

What makes ARMEX the best baking soda abrasive?

The Original

ARMEX is the original baking soda based abrasive. In 1985 it was Church & Dwight Co., Inc. makers of ARM & HAMMER products that while working with the engineers restoring the Statue of Liberty decided to try baking soda as an abrasive. Following the success of soda blasting, Church & Dwight partnered with equipment maker Schmidt Manufacturing to optimize the process, both the equipment and the media, for commercial application. The chemists at Church & Dwight have developed application specific soda blasting abrasives to meet industry requirements worldwide.

Why Baking Soda Blasting?

- It’s granular – a particulate suitable for use in pressure pots, cabinet systems and as an injection media for pressure washer systems.

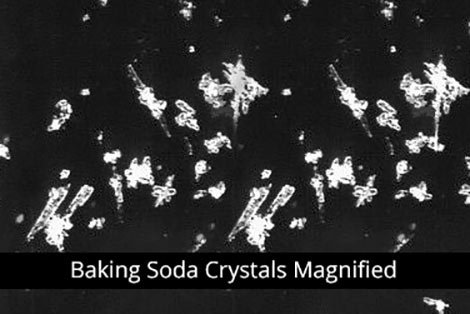

- It’s sharp – baking soda crystals delivered under relatively low pressure but at high velocity will scour virtually any coating from any substrate.

- It’s friable – meaning it fractures into smaller particles intensifying the cleaning action while softening the impact on substrates.

- It’s relatively soft – with a Moh’s hardness of 2.5, it will not damage most substrates.*

- It’s near neutral pH of 8.2 – provides a superior worker and environmental profile, before, during, and after use.

- It’s water soluble – Baking Soda, the main ingredient, is 100% water soluble… This feature alone eliminates particle ingression issues for anyone working on intricate surfaces where entrapment of other types of abrasives can void warranties or cause critical failures.

* Always do a test patch prior to general use to determine suitability