Removing Paint and Grease from Aluminum Engine Parts (19-B-102)

Client was looking for a new cleaning process to improve their cleaning performance, eliminate process steps, eliminate hazardous chemical/waste, and remove carbon and trapped contaminates.

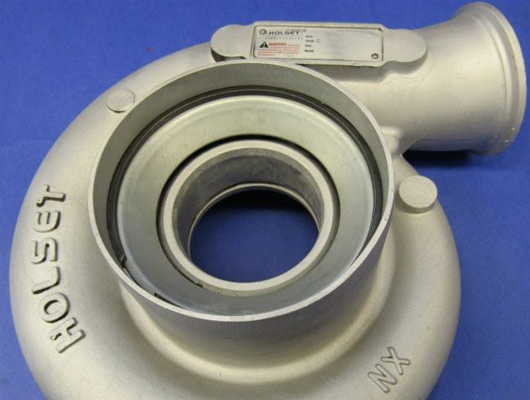

Before

After

Cleaning Trial Type

Abrasive Cleaning

Industry

Substrate

Aluminum

Description of Part(s)

Aluminum Turbo C-cases

Recommended Media

Machine Used

Dry Blast Cabinet

Type of Blasting

Contained

Post Cleaning

Fresh water rinse followed by air pressure drying

Soil

Baked on Carbon, Grease, Grime, Paint

Recommendation

The ArmaKleen Technical Center recommends using ARMEX™ Blast Media - Flow XL with a #4 Performance Nozzle at a blasting pressure of 60 psi and a media flow rate of 1.0 lb/min or ARMEX™ Blast Media – Turbine Formula with a #4 Performance Nozzle at a blasting pressure of 60 psi and a media flow rate of 0.75 lbs/min for the cleaning of grime, grease, e-coat paint, and carbon.