Cleaning Nickel Superalloy (IN939) with Soda Blasting Media (19-B-129)

Customer was looking for a new process, eliminate process steps, reduce their cleaning costs while removing dis-colorization and stains from the part while keeping the ceramic coating intact.

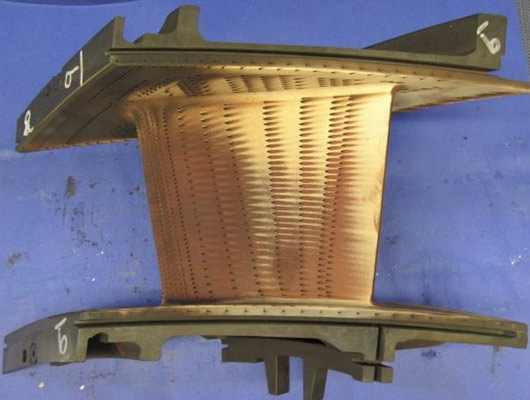

Before

After

Cleaning Trial Type

Abrasive Cleaning

Industry

Description of Part(s)

Nickle Gas Turbine Vane

Media Used

Machine Used

Dry Blast Cabinet

Post Cleaning

Fresh water rinse and air pressure dried

Soil

Glue/Adhesive, Grease, Rust/Oxides, Shop Dirt

Recommendation

ARMEX™ recommends ARMEX™ Flow Formula XL– with a #4 Performance Nozzle at 100 psi blasting pressure in a Dry Blast Cabinet.